It's about time I started a thread for this car.

I picked up this '02 from Carlos at Condor Speed Shop down here in Florida in October 2014. My turbo e30 had just been totalled & I was searching for something new. This popped up and I found it tough to say no. The car is a 1973 malaga 2002 with unknown mileage. The m10 it came with was supposedly “built”; apparently it had cams & some head work.

The car when I bought it had been sitting for a few years. Somebody before Carlos had decided to paint the hood, roof, and trunk with house paint in a poor attempt to stall the spread of some rust. Hopefully I'll get around to refreshing the body later this year.

Next I pulled the old m10. It only took a couple of minutes to get out.

M10 removed:

Next I cleaned the car with a pressure cleaner; I rolled it out of the shop & snapped a few pics.

Of course I had to test fit my old RS's!

And then I decided to widen them a little......so to help them fit I ordered some turbo flares for the car.

After thinking my options over & perusing a few good threads, I decided to drop in my old turbo m20 motor. Before I dropped it in I'd do all new seals/gaskets and refresh it. SO I ordered my parts & once they were on their way I started prepping the motor/chassis.

The wiring harness was an easy enough task. After stripping the body harness of all the old loom I was able to trace the wires back a few feet to see their original color. Using the “6 does go into 2” DIY, I was able to locate the wires that I needed and wire them up to an e30 c101 body harness side plug. Then I ran a few new wires, like the fuel pump +12v wire, and labeled them all.

I ended up using Sin City mounts, which place the motor pretty high up. I had a very tough time getting these to work, and after exchanging many emails with the company I had apparently been sent the wrong mounts, which explained why they didn't work. I was getting tired of waiting around though, so I ended up modifying the subframe to make these work. I had to push the passenger subframe holes out about an inch and then modify the drivers side motor mount.

Said motor mounts:

I decided to mess around and run barrels as lips on my old RS's to see what it would look like on the car

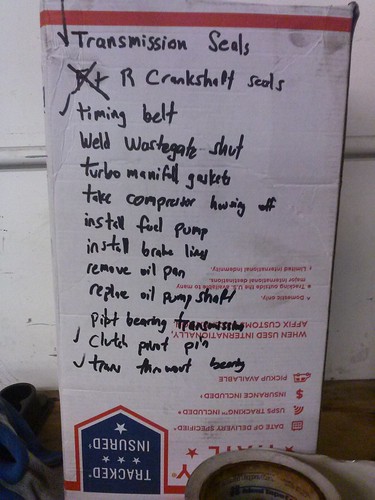

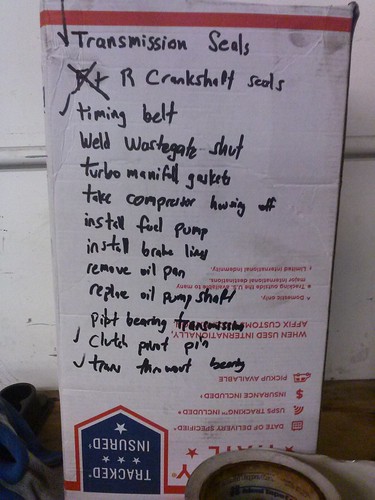

Tons of to-do lists help me stay organized lol

Here's the trans brace I made

Picked up some decent seats. Still need to make brackets for them

Drilled & tapped the compressor housing for a barbed nipple instead of the dumb press in plastic fitting it came with

The transmission tunnel widening made this swap nearly impossible. I realize that not a lot of people run a g260 transmission because it requires a "little bit" of extra hammering, but I didnt realize just how much that was until I got everything in place.

Pre BFH:

The beginning of the trans tunnel surgery

Here's a pic of how high the trans sits in the tunnel

Had to cut out a few rusty spots on the floor board & replace them with some good metal

I ended up drilling the firewall to run the harness thru

Of course I'm gonna need some great bushings to run on this car to support the m20 and keep everything from falling apart........

I test fitted the turbo flares to motivate me to finish the swap lol

Then comes the wheels...........

Transformed my old barrels into lips with the help of some friends at Spintech

Rear:

Front:

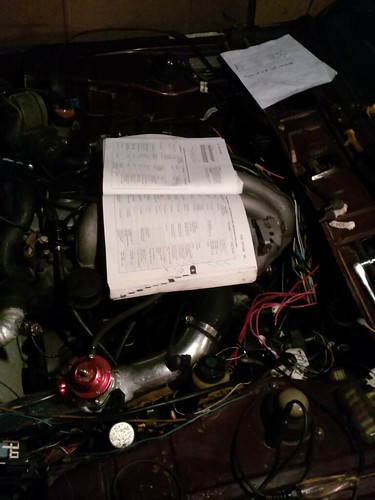

While the motor wasn't in the car I figured it would be a good idea to refresh all the seals & rotating parts on the driveline. So I installed a new rear main seal, timing belt, SS brake/clutch lines, new center support bearing for the driveshaft, new guibo, a fresh, non cracked oil pan, I resealed the whole transmission(input, output shafts and the shifter selector rod seal), all new turbo manifold gaskets, fuel pressure regulator, and a variety of other things.

Got the flywheel resurfaced while everything was apart & also did a new clutch/pressure plate

Test fitted the motor again for the 20th time

I'll post the rest of the updates tomorrow

I picked up this '02 from Carlos at Condor Speed Shop down here in Florida in October 2014. My turbo e30 had just been totalled & I was searching for something new. This popped up and I found it tough to say no. The car is a 1973 malaga 2002 with unknown mileage. The m10 it came with was supposedly “built”; apparently it had cams & some head work.

The car when I bought it had been sitting for a few years. Somebody before Carlos had decided to paint the hood, roof, and trunk with house paint in a poor attempt to stall the spread of some rust. Hopefully I'll get around to refreshing the body later this year.

Next I pulled the old m10. It only took a couple of minutes to get out.

M10 removed:

Next I cleaned the car with a pressure cleaner; I rolled it out of the shop & snapped a few pics.

Of course I had to test fit my old RS's!

And then I decided to widen them a little......so to help them fit I ordered some turbo flares for the car.

After thinking my options over & perusing a few good threads, I decided to drop in my old turbo m20 motor. Before I dropped it in I'd do all new seals/gaskets and refresh it. SO I ordered my parts & once they were on their way I started prepping the motor/chassis.

The wiring harness was an easy enough task. After stripping the body harness of all the old loom I was able to trace the wires back a few feet to see their original color. Using the “6 does go into 2” DIY, I was able to locate the wires that I needed and wire them up to an e30 c101 body harness side plug. Then I ran a few new wires, like the fuel pump +12v wire, and labeled them all.

I ended up using Sin City mounts, which place the motor pretty high up. I had a very tough time getting these to work, and after exchanging many emails with the company I had apparently been sent the wrong mounts, which explained why they didn't work. I was getting tired of waiting around though, so I ended up modifying the subframe to make these work. I had to push the passenger subframe holes out about an inch and then modify the drivers side motor mount.

Said motor mounts:

I decided to mess around and run barrels as lips on my old RS's to see what it would look like on the car

Tons of to-do lists help me stay organized lol

Here's the trans brace I made

Picked up some decent seats. Still need to make brackets for them

Drilled & tapped the compressor housing for a barbed nipple instead of the dumb press in plastic fitting it came with

The transmission tunnel widening made this swap nearly impossible. I realize that not a lot of people run a g260 transmission because it requires a "little bit" of extra hammering, but I didnt realize just how much that was until I got everything in place.

Pre BFH:

The beginning of the trans tunnel surgery

Here's a pic of how high the trans sits in the tunnel

Had to cut out a few rusty spots on the floor board & replace them with some good metal

I ended up drilling the firewall to run the harness thru

Of course I'm gonna need some great bushings to run on this car to support the m20 and keep everything from falling apart........

I test fitted the turbo flares to motivate me to finish the swap lol

Then comes the wheels...........

Transformed my old barrels into lips with the help of some friends at Spintech

Rear:

Front:

While the motor wasn't in the car I figured it would be a good idea to refresh all the seals & rotating parts on the driveline. So I installed a new rear main seal, timing belt, SS brake/clutch lines, new center support bearing for the driveshaft, new guibo, a fresh, non cracked oil pan, I resealed the whole transmission(input, output shafts and the shifter selector rod seal), all new turbo manifold gaskets, fuel pressure regulator, and a variety of other things.

Got the flywheel resurfaced while everything was apart & also did a new clutch/pressure plate

Test fitted the motor again for the 20th time

I'll post the rest of the updates tomorrow

:

:

I'm coming down south to visit soon, i better see this cah while i'm there.

I'm coming down south to visit soon, i better see this cah while i'm there.

Comment