hi. i'm Anti. i'm a 23 year old living in Sydney, Australia. for the last 36 months or so I've been working on my project car, a j-spec 1989 twin turbo 2+2 manual 300ZX originally in black. it's my second z32 after a 2+0 red NA, and the first time I've really worked on a car. since this build has been going on for a while i'll run through some condensed bits from the last few years before getting up to the present.

i received this car in pretty awful condition, the only selling point being a motor that'd just gone in with all new seals, gaskets, 100k service, etc. the rest of it was a shagged out heap of scrapyard shit. unregistered, leaking, blistering partially primed paint, red vinyl interior, china spec wheels, neons, the lot.

the goals for the car at first were KISS - bolt ons, pretty it up, paint and enjoy.

a quick run down of the car while the plan was in motion currently is as follows. adjustable suspension, dumped and pretty flush, fully up to scratch engine with brand new high flowed OEM turbos, OEM recaros and gauges/sound system, wire tucked engine bay, bigger brakes, clutch and steel driveshaft, etc etc. then about two years in... everything changed! more on that later. in the time i've owned the car I've done approximately 3000 kilometers in it as it's been total project car status.

it's still not finished, and never reached the point of paint as it was always the intention to do that last. i find it hard to put into text what has gone into this vehicle on my behalf - more than just money for parts and time for fitting them. all work done was in my parents' garage, with skills I developed while realising what i was doing at the time. i have invested everything into this car; not only all my money and hundreds maybe thousands (yes) of hours of my time, but my future and my passion. excitedly, the best has still yet to come. the thread starts when I got the car, not knowing which way to swing a ratchet.

to catch up i'll summarise different aspects into a post each. i guess I'll start with the body

- ADM NA front bar

- ADM front dummy lights (modified, now functional)

- Fog light ducts

- Series 1 badgeless nose panel

- Escort Racing FRP vented bonnet

- Ganador wing mirrors

- Driven Authority CSL-R lip wing

- 2K spec tail lights

- Altai center panel (modified, lights up red)

- 35% tint

recentish photo before going back into the garage for the long term

below is as far as I got with the bay while I had the original engine. wiring tucked, battery in the boot, fuel filter rear mounted, HICAS deleted, etc etc. for a while, the plan was to pretty this up, get a tune, paint the shell and enjoy motoring.

Then the motor then unexpectedly blew on the dyno and that massively changed the direction of the build. back into the garage, the following has occurred and/or is currently occurring

- total rewire

- stitch welded chassis

- complete bay shave

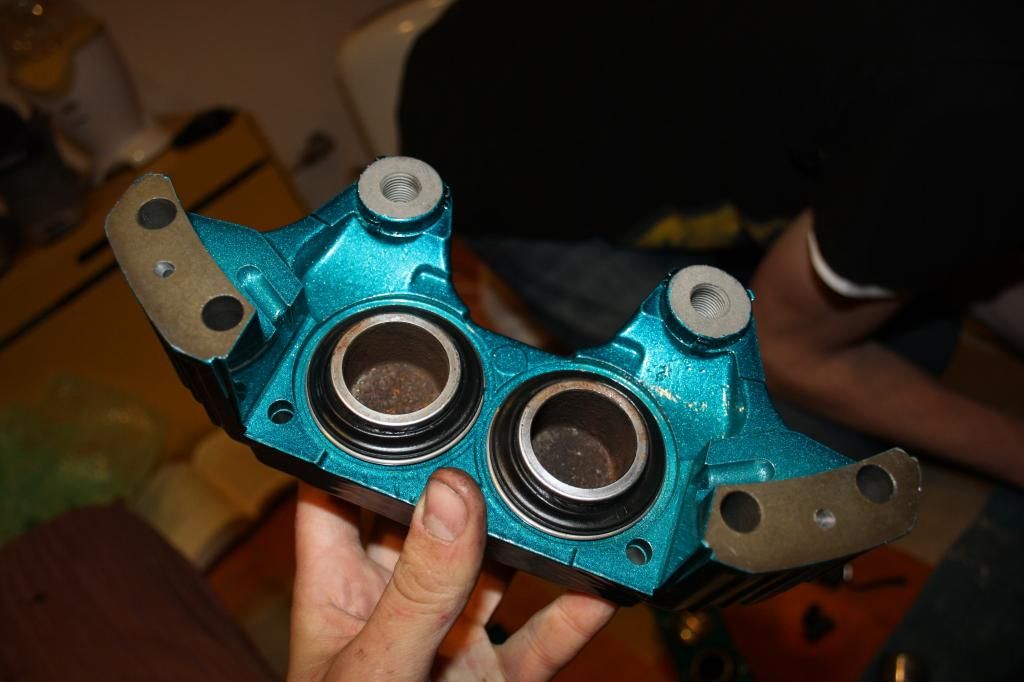

- 6 piston / 14" rotors on all corners

- old school work wheel rebarreling project

- fully built top to bottom vg30dett

- compound turbo set up

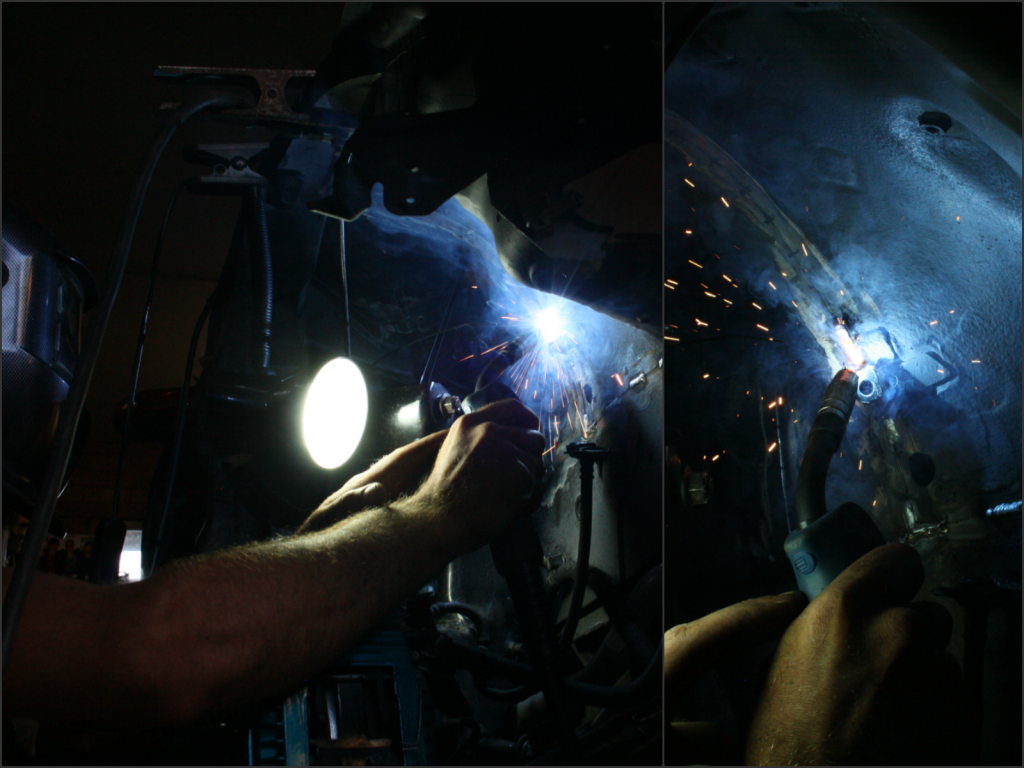

- welding and fab work (i'm learning so baby steps!)

with plenty more coming... kind of got away from me tbh

more on that later. be back soon to fill you guys in more.

-A

i received this car in pretty awful condition, the only selling point being a motor that'd just gone in with all new seals, gaskets, 100k service, etc. the rest of it was a shagged out heap of scrapyard shit. unregistered, leaking, blistering partially primed paint, red vinyl interior, china spec wheels, neons, the lot.

the goals for the car at first were KISS - bolt ons, pretty it up, paint and enjoy.

a quick run down of the car while the plan was in motion currently is as follows. adjustable suspension, dumped and pretty flush, fully up to scratch engine with brand new high flowed OEM turbos, OEM recaros and gauges/sound system, wire tucked engine bay, bigger brakes, clutch and steel driveshaft, etc etc. then about two years in... everything changed! more on that later. in the time i've owned the car I've done approximately 3000 kilometers in it as it's been total project car status.

it's still not finished, and never reached the point of paint as it was always the intention to do that last. i find it hard to put into text what has gone into this vehicle on my behalf - more than just money for parts and time for fitting them. all work done was in my parents' garage, with skills I developed while realising what i was doing at the time. i have invested everything into this car; not only all my money and hundreds maybe thousands (yes) of hours of my time, but my future and my passion. excitedly, the best has still yet to come. the thread starts when I got the car, not knowing which way to swing a ratchet.

to catch up i'll summarise different aspects into a post each. i guess I'll start with the body

- ADM NA front bar

- ADM front dummy lights (modified, now functional)

- Fog light ducts

- Series 1 badgeless nose panel

- Escort Racing FRP vented bonnet

- Ganador wing mirrors

- Driven Authority CSL-R lip wing

- 2K spec tail lights

- Altai center panel (modified, lights up red)

- 35% tint

recentish photo before going back into the garage for the long term

below is as far as I got with the bay while I had the original engine. wiring tucked, battery in the boot, fuel filter rear mounted, HICAS deleted, etc etc. for a while, the plan was to pretty this up, get a tune, paint the shell and enjoy motoring.

Then the motor then unexpectedly blew on the dyno and that massively changed the direction of the build. back into the garage, the following has occurred and/or is currently occurring

- total rewire

- stitch welded chassis

- complete bay shave

- 6 piston / 14" rotors on all corners

- old school work wheel rebarreling project

- fully built top to bottom vg30dett

- compound turbo set up

- welding and fab work (i'm learning so baby steps!)

with plenty more coming... kind of got away from me tbh

more on that later. be back soon to fill you guys in more.

-A

Love the rad parts collection, you are moving right along, good progress in here!

Love the rad parts collection, you are moving right along, good progress in here!

Comment