This is going to be a bit more vanilla stance than what you guys are probably used to, but somebody may like it.

Before I get into the build proper, here's the specs sheet so far

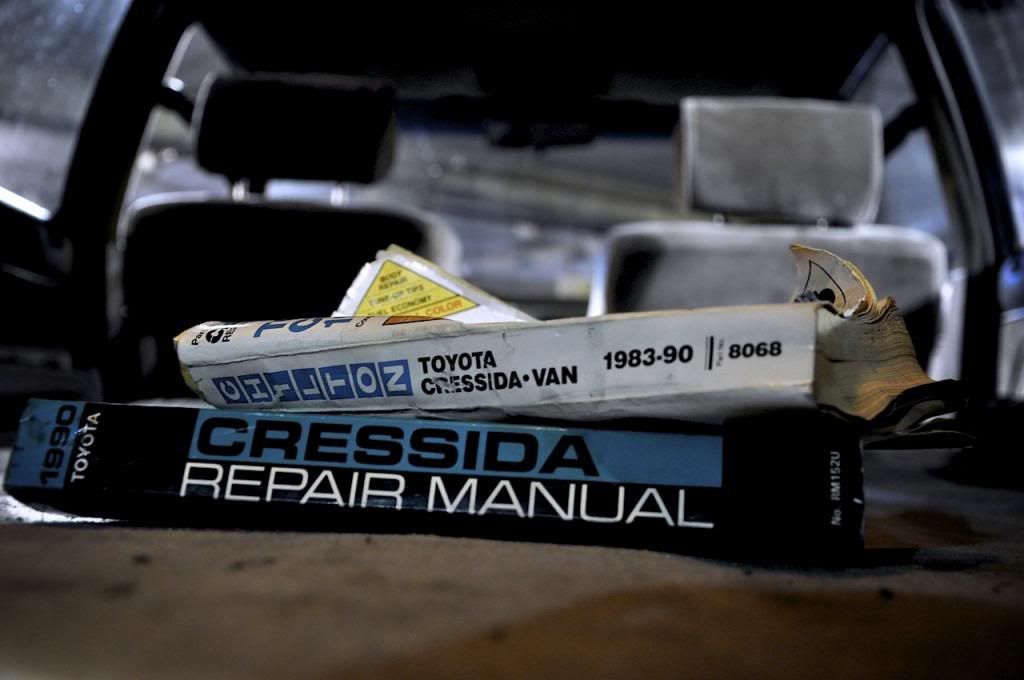

1986 Toyota Cressida wagon

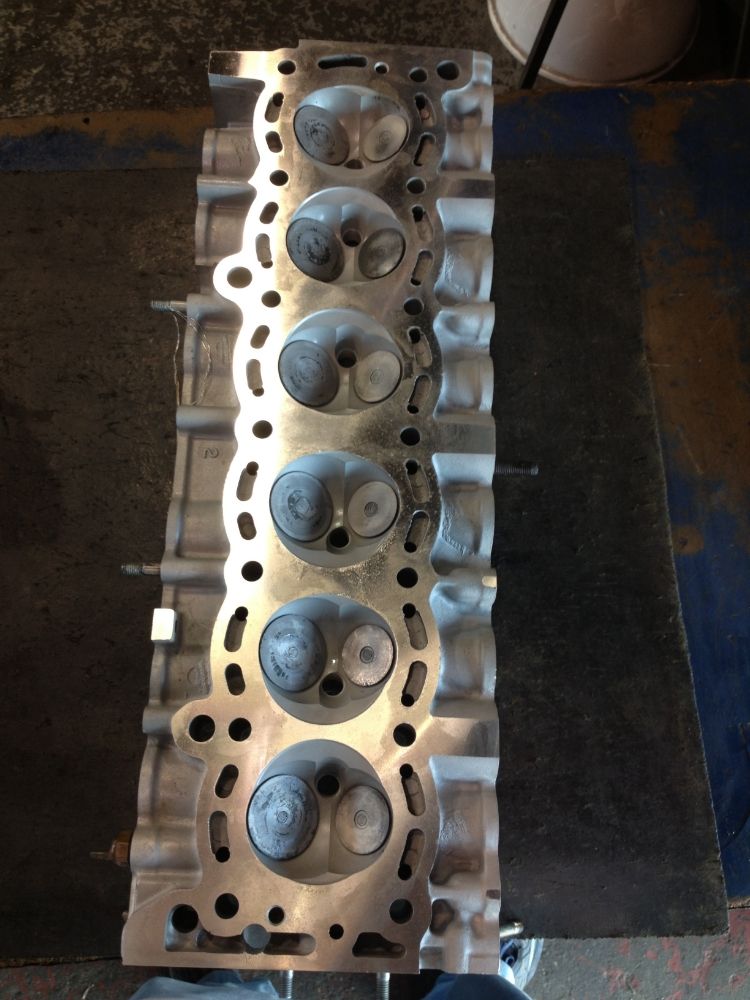

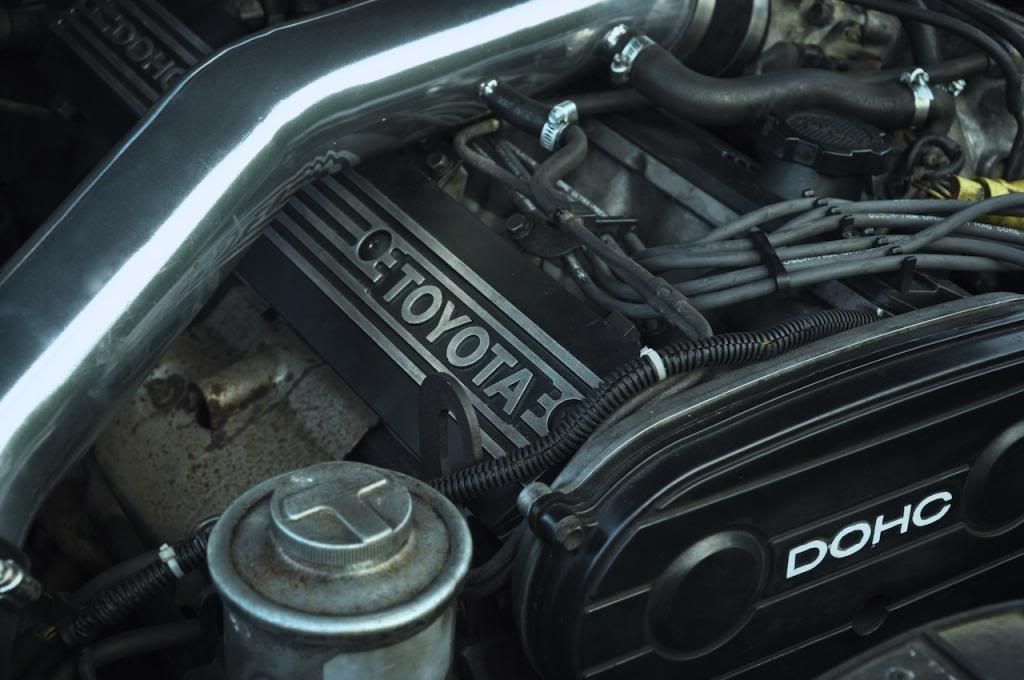

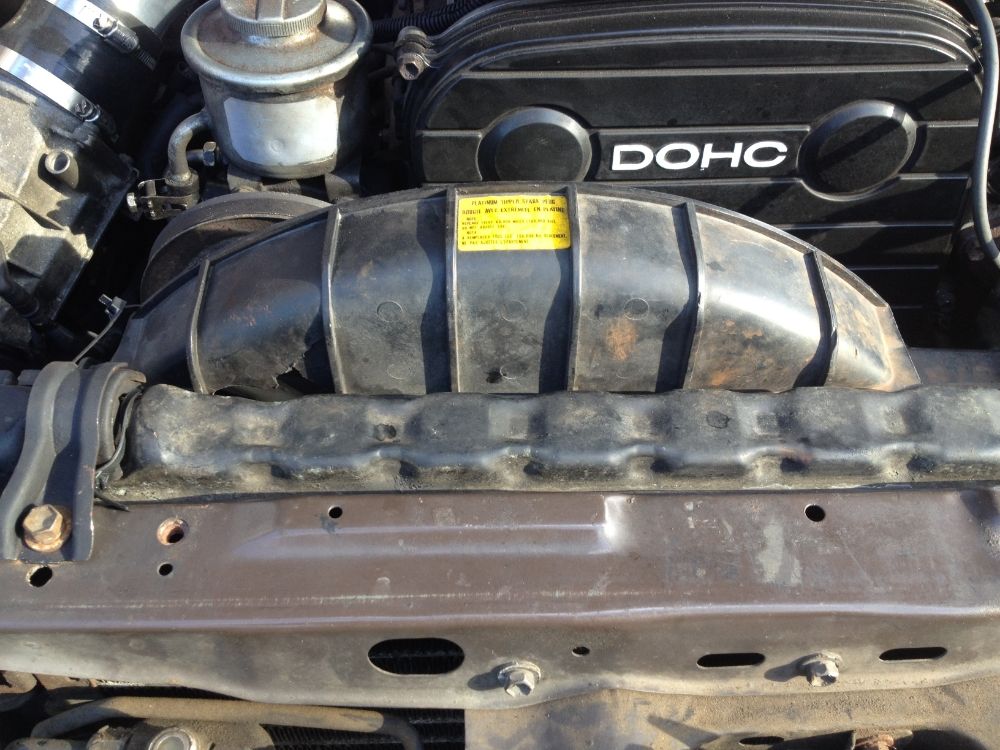

5M-GE

RabidChimp ceramic coated intake pipe with K&N filter

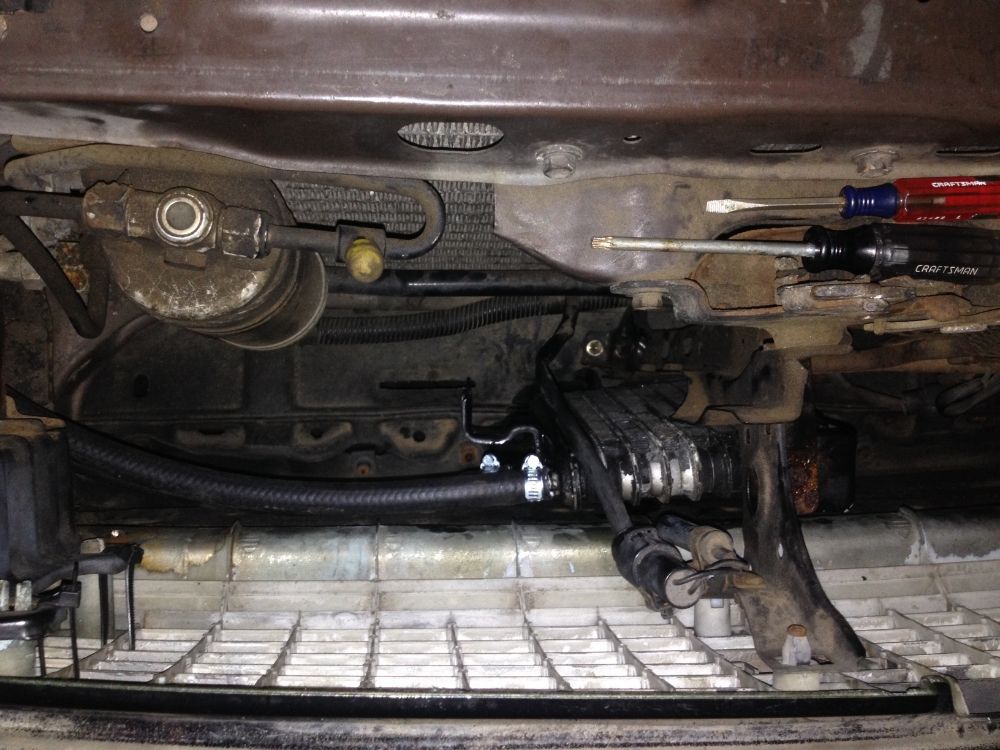

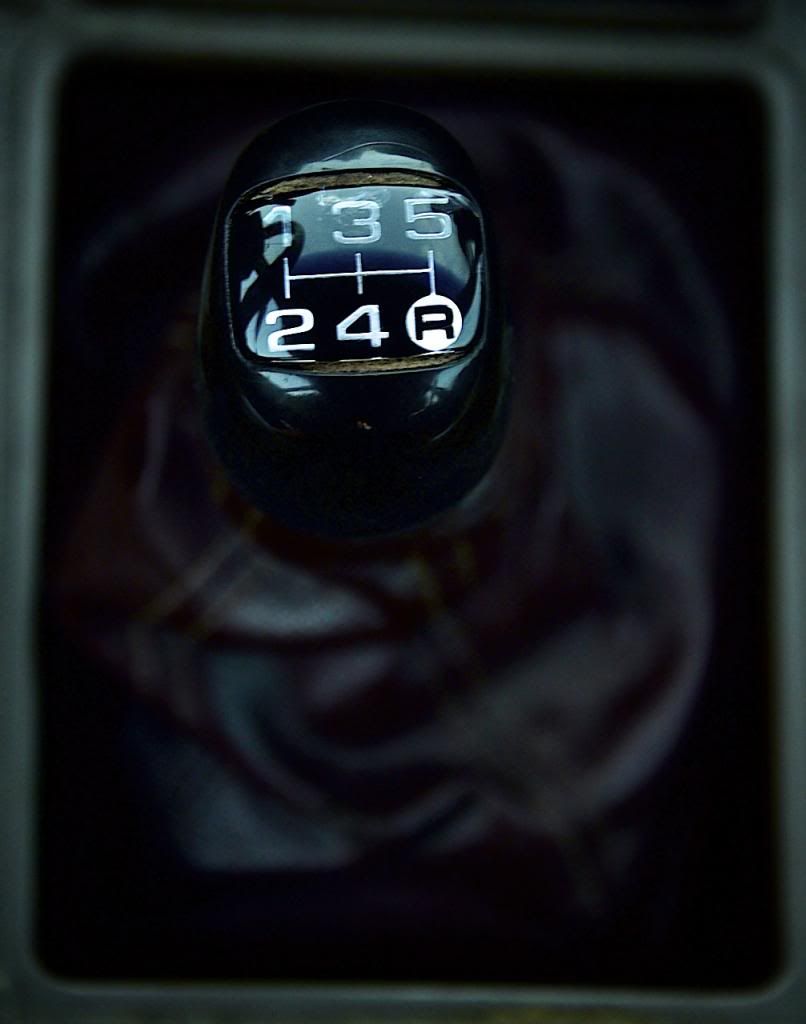

W58 from a MA70 Supra

Custom driveshaft

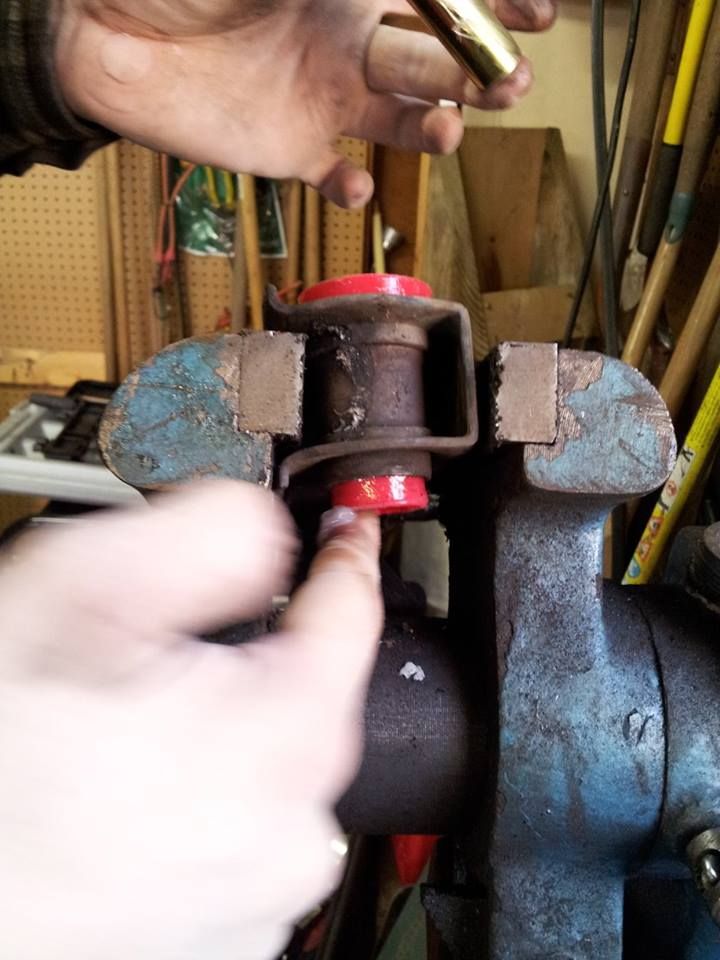

AE86 clutch pedal

MA60 Supra clutch MC

DriftMotion braided clutch line

All new brake system (MC, lines, pads, calipers, rotors, shoes, drums, wheel cylinders)

All new engine, trans, and rear end seals

Energy Suspension front control arm poly bushings

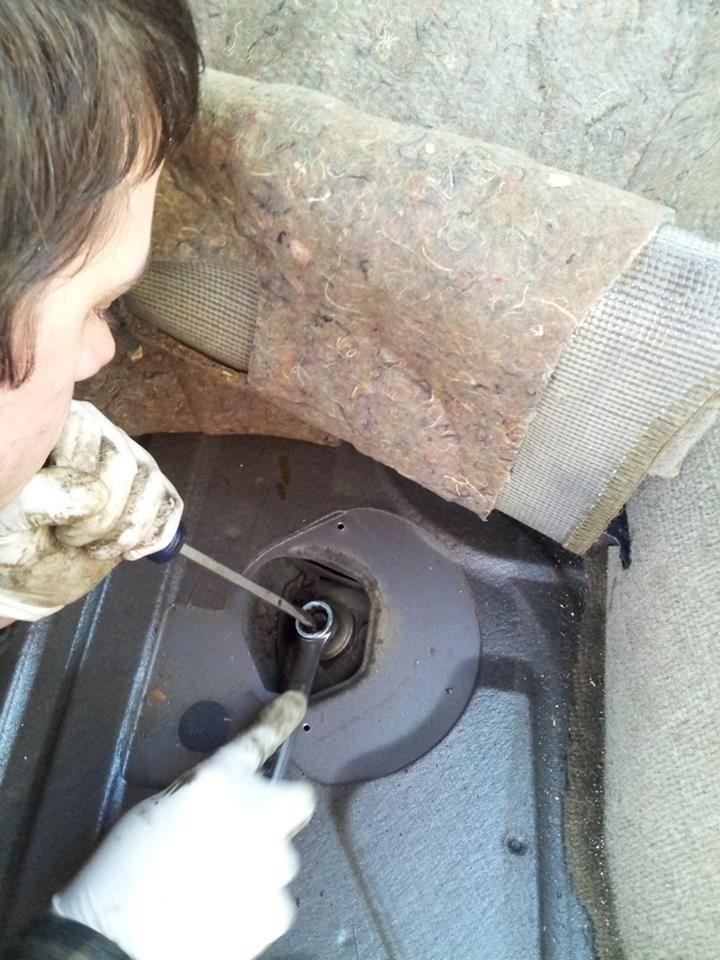

Shortened front strut housings, MR2 KYB AGX inserts, T3 weld-on coilovers (400 lb springs), T3 camber plates, T3 RCA's

Custom 400lb rear springs

Camaro KYB AGX rear shocks

Home-made poly bushings in the 4 links

Custom T3 panhard rod

P-Type Celica-Supra wheels (14x7 +8)

195/70R14 rear, 185/60R14 front

Proper build will be below!

Before I get into the build proper, here's the specs sheet so far

1986 Toyota Cressida wagon

5M-GE

RabidChimp ceramic coated intake pipe with K&N filter

W58 from a MA70 Supra

Custom driveshaft

AE86 clutch pedal

MA60 Supra clutch MC

DriftMotion braided clutch line

All new brake system (MC, lines, pads, calipers, rotors, shoes, drums, wheel cylinders)

All new engine, trans, and rear end seals

Energy Suspension front control arm poly bushings

Shortened front strut housings, MR2 KYB AGX inserts, T3 weld-on coilovers (400 lb springs), T3 camber plates, T3 RCA's

Custom 400lb rear springs

Camaro KYB AGX rear shocks

Home-made poly bushings in the 4 links

Custom T3 panhard rod

P-Type Celica-Supra wheels (14x7 +8)

195/70R14 rear, 185/60R14 front

Proper build will be below!

Comment