We left off with the engine in the bay for the last time and now it's just ticking off items to get it ready for start up. These are the small jobs that suck up time but don't look that impressive in pictures. Either way, progress is progress!

First up was the serpentine belt. We relocated the power steering pump so a different belt was needed. Here it is all together. Relocating the PS pump made it so clearancing the battery tray area isn't required, but not a required mod for the swap.

Next was the heater core lines. Obviously there aren't any VK56 to S13 heater core hoses at the local parts store so here's the solution for now.

And a pic of the part numbers for reference later. Those and two 5/8" to 3/4" hose splices and eight 1.24" hose clamps.

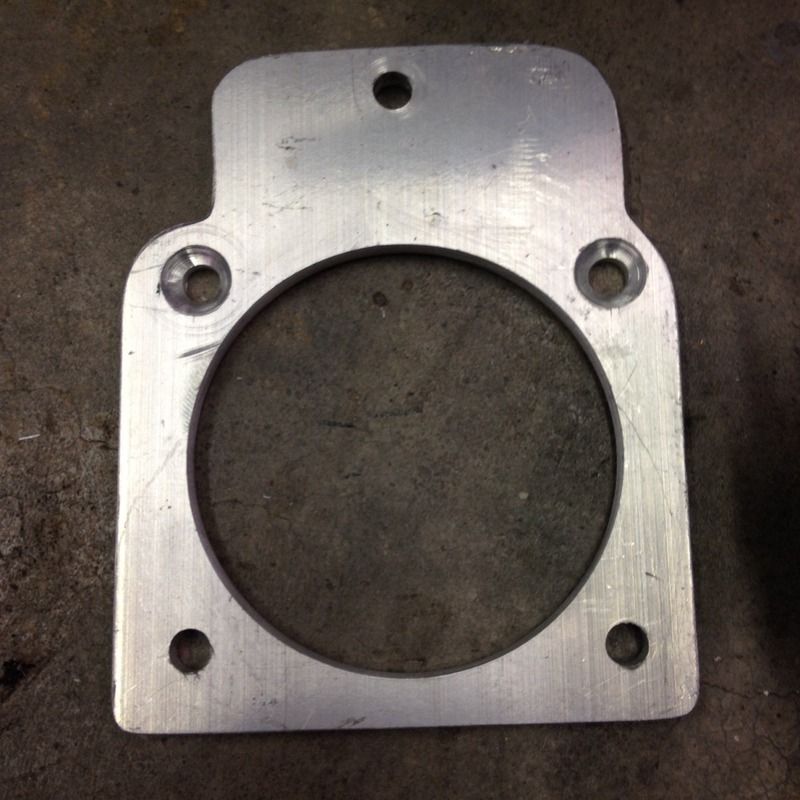

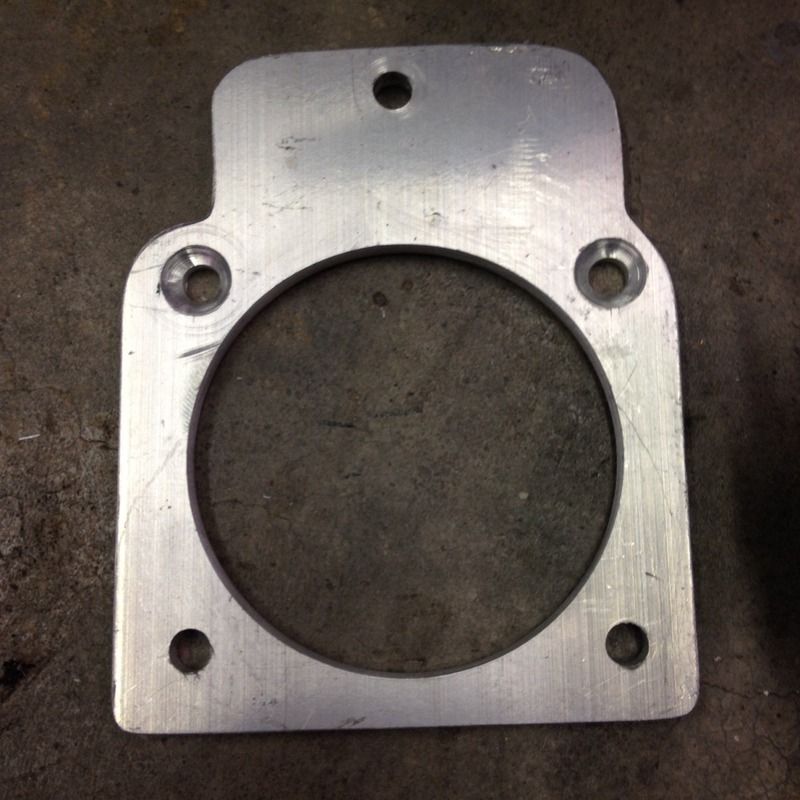

We needed a throttle body solution as well. The stock Titan TB is DBW which does us no good so we opted for a LS2 TB. This one came from a seller on eBay freshly ported (80-90mm) and cheaper than OEM units including the sensors. There was a lot of positive feedback on them so it seemed like a win-win. The stock VK56 TB is only 70mm and a common gripe in the Titan community. We'll be developing an intake manifold down the road so this serves that purpose as well since we for sure won't be making it with a restrictive 70mm opening. It'll be cool to do back to back dyno pulls swapping only the intake manifold and see the differences.

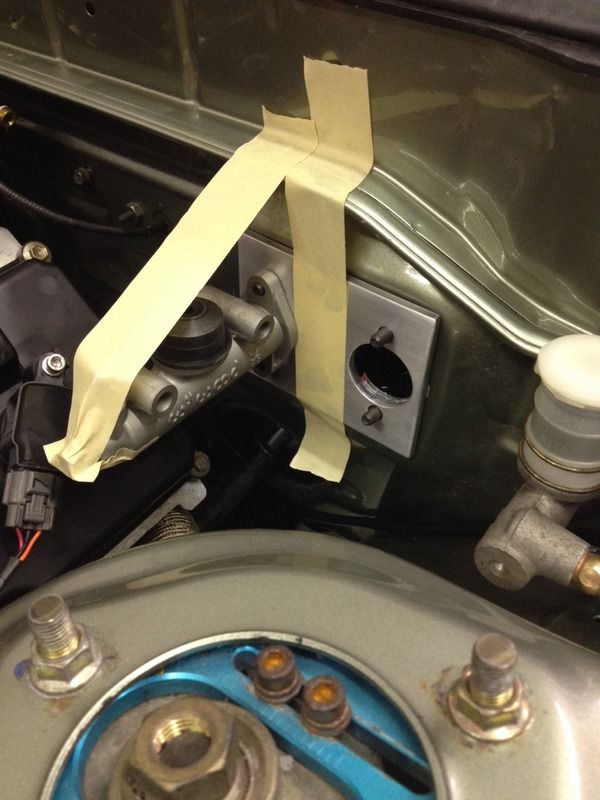

To make it work, Greg made up a little adapter plate.

And bolted up it looks pretty darn good! This is an aspect of the build we haven't touched until now so it's kind of cool to see it come together.

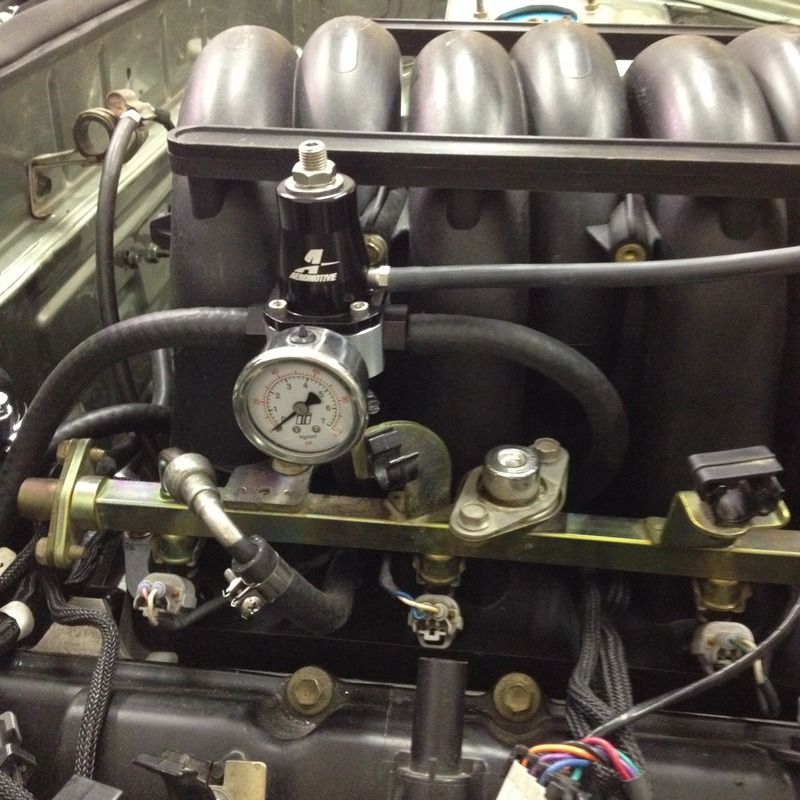

Intake on the car and the starter bolted on underneath, the engine is looking like an engine!

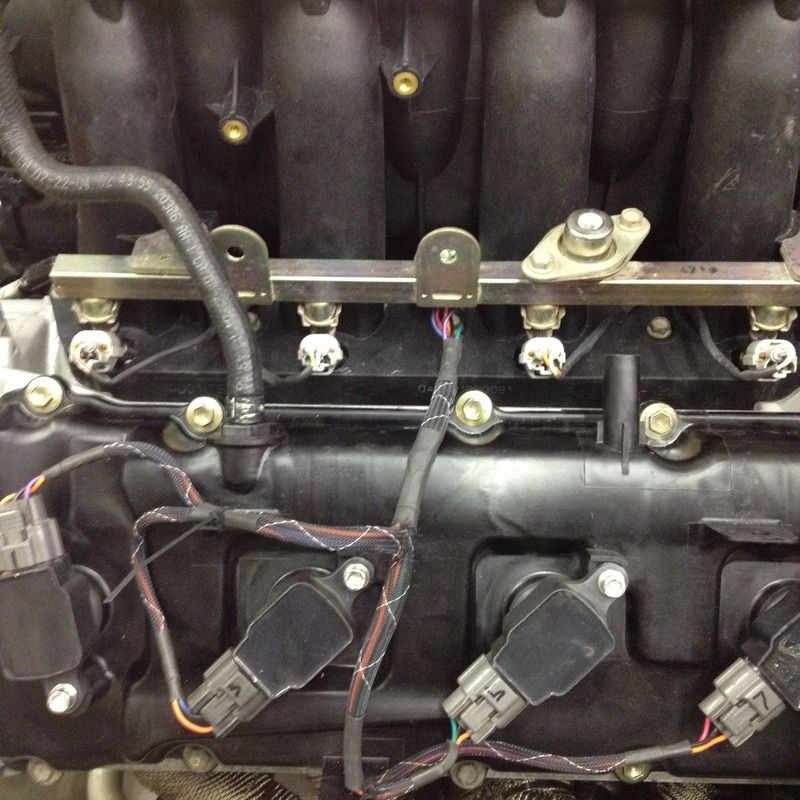

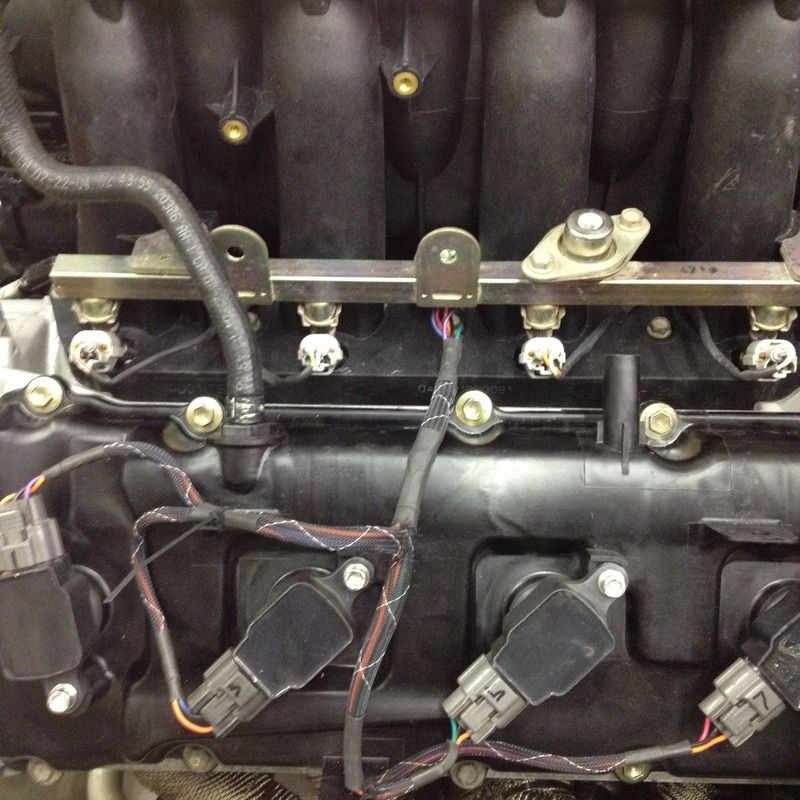

This means we can move on to the other most fun aspect of building a car - wiring! Actually, if you'll recall, we kind of cheated here and bought Forsberg's old BigStuff3 ECU and wiring full setup from his old Z. This helped direct the TB purchase and simplified the wiring situation since it's nearly plug and play.

Woot woot! It's coming together and looking like a complete engine package.

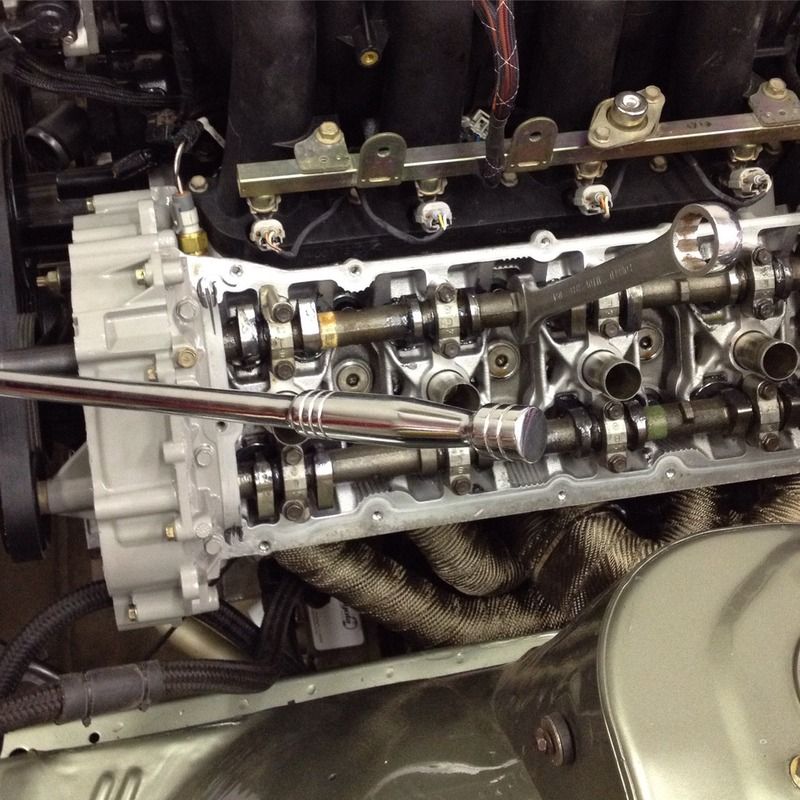

This being the first of a few cars we've got planned, Greg laid out the stock VK harness to make a template. We'll be exploring different ECU options the next time around (probably AEM or MS3Pro since they're so popular and "supported") and likely making our own engine harness.

Can we turn the key yet???

First up was the serpentine belt. We relocated the power steering pump so a different belt was needed. Here it is all together. Relocating the PS pump made it so clearancing the battery tray area isn't required, but not a required mod for the swap.

Next was the heater core lines. Obviously there aren't any VK56 to S13 heater core hoses at the local parts store so here's the solution for now.

And a pic of the part numbers for reference later. Those and two 5/8" to 3/4" hose splices and eight 1.24" hose clamps.

We needed a throttle body solution as well. The stock Titan TB is DBW which does us no good so we opted for a LS2 TB. This one came from a seller on eBay freshly ported (80-90mm) and cheaper than OEM units including the sensors. There was a lot of positive feedback on them so it seemed like a win-win. The stock VK56 TB is only 70mm and a common gripe in the Titan community. We'll be developing an intake manifold down the road so this serves that purpose as well since we for sure won't be making it with a restrictive 70mm opening. It'll be cool to do back to back dyno pulls swapping only the intake manifold and see the differences.

To make it work, Greg made up a little adapter plate.

And bolted up it looks pretty darn good! This is an aspect of the build we haven't touched until now so it's kind of cool to see it come together.

Intake on the car and the starter bolted on underneath, the engine is looking like an engine!

This means we can move on to the other most fun aspect of building a car - wiring! Actually, if you'll recall, we kind of cheated here and bought Forsberg's old BigStuff3 ECU and wiring full setup from his old Z. This helped direct the TB purchase and simplified the wiring situation since it's nearly plug and play.

Woot woot! It's coming together and looking like a complete engine package.

This being the first of a few cars we've got planned, Greg laid out the stock VK harness to make a template. We'll be exploring different ECU options the next time around (probably AEM or MS3Pro since they're so popular and "supported") and likely making our own engine harness.

Can we turn the key yet???

Comment