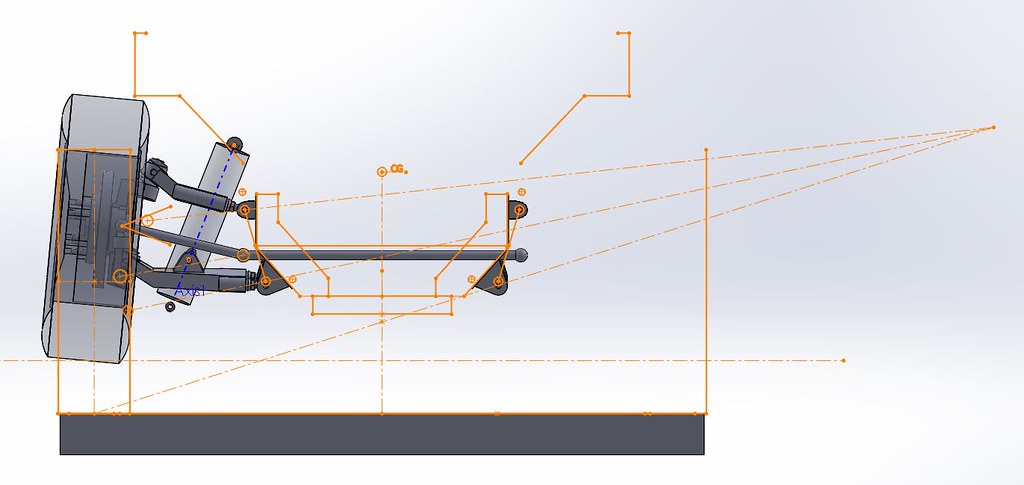

Engine mounts and transmission mount are finished.

Driver:

Passenger:

Trans:

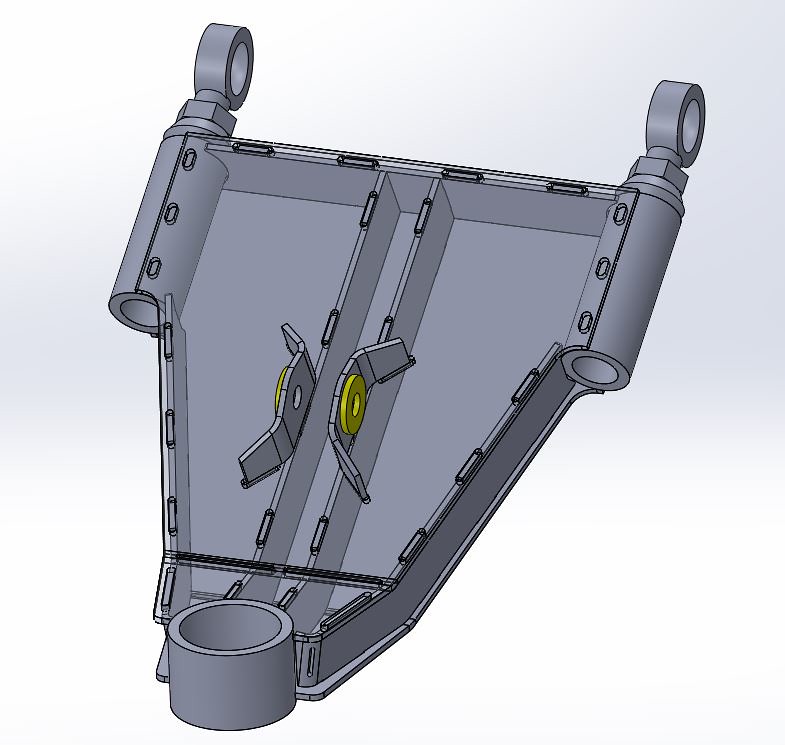

And I've started mocking up the new transmission tunnel. I'll also be mounting the hydro hand brake to this, and hopefully adding a couple cup holders. I think I'll go one inch narrower in the rear of the tunnel than this mock-up. Also keep in mind it needs to slide slightly further forward than pictured but I have to dig more insulation off the firewall piece by piece till I can get it in there.

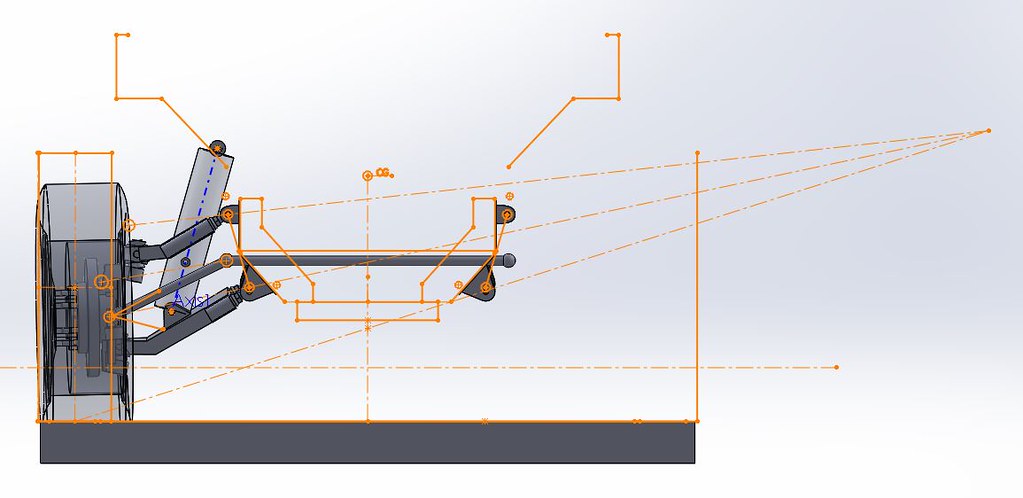

Driver:

Passenger:

Trans:

And I've started mocking up the new transmission tunnel. I'll also be mounting the hydro hand brake to this, and hopefully adding a couple cup holders. I think I'll go one inch narrower in the rear of the tunnel than this mock-up. Also keep in mind it needs to slide slightly further forward than pictured but I have to dig more insulation off the firewall piece by piece till I can get it in there.

Comment