Announcement

Collapse

No announcement yet.

The Fabrication/Welding Thread

Collapse

This is a sticky topic.

X

X

-

Leave a comment:

-

Greg I really hope you end up fitting BMW headers on the m103, if you do I'll pay you to make a second set!

Leave a comment:

-

No idea if it's still relevant or what benz you have. But if its a 124ish era, and a v24 motor like 300-24/320/280 or even maybe a 300 v12, you can search local junkyards or ebay for a set of later stainless manifolds. as they have a fat flange that can be used for that.Originally posted by Greg View PostI picked up some eBay BMW stainless headers from a friend to put on my Mercedes. I'm sure the stainless is inferior since they are already rusting. This is more or less a trial run to see how they fit and work. Can I cut the cast flange off of my manifolds to weld to the stainless? My other option is buy a flange from Australia at $118 shipped. It's mild steel.

Edit: that custom step is da bomb

Leave a comment:

-

You can most definitely do so but be careful; ebay stainless tends to be very thin and welds pretty poorly with a MIG (as does all stainless). Blow-through is easy if you're not paying attention.Originally posted by Greg View PostI picked up some eBay BMW stainless headers from a friend to put on my Mercedes. I'm sure the stainless is inferior since they are already rusting. This is more or less a trial run to see how they fit and work. Can I cut the cast flange off of my manifolds to weld to the stainless? My other option is buy a flange from Australia at $118 shipped. It's mild steel.

I would also suggest grabbing an exhaust manifold from the junkyard so you aren't cutting up your only good one for a flange.

Leave a comment:

-

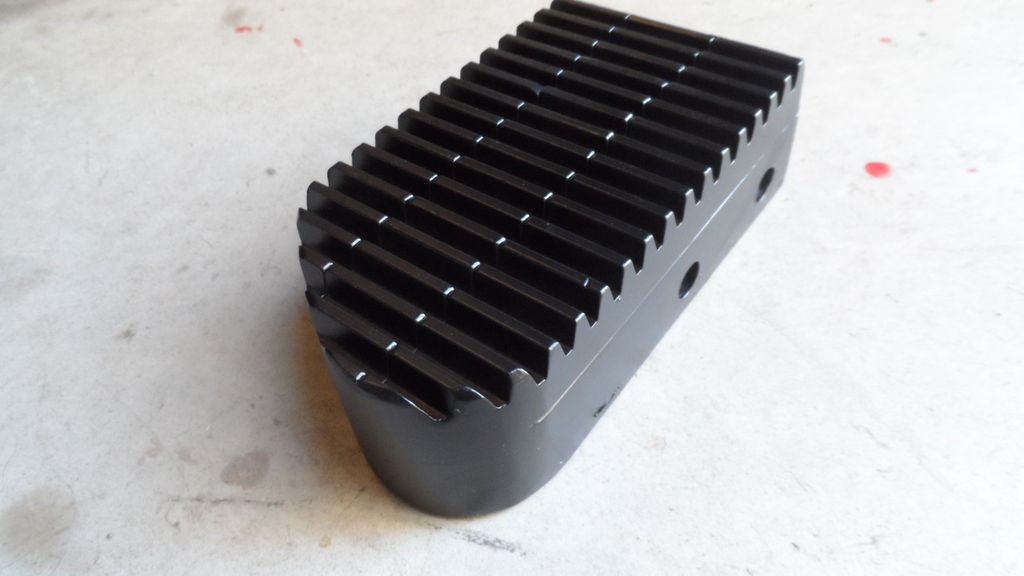

I made a tow hook and oil checking step for my 79 K10. the step is mounted to the push bar and the hook is bolted to the frame

the hook was cut out of a piece of scrap i had. it is about 3/4" thick and my Hypertherm 30xp isnt even rated to cut that much so im lucky i got it as smooth as i did. its very hard to trim little bits off like that so its not perfectly shaped.

i made the step out of a scrap bracket and what im guessing is a section of track for a machine of some sort. we have the same track on the floor for the machines to open up on at my work.

Leave a comment:

-

I picked up some eBay BMW stainless headers from a friend to put on my Mercedes. I'm sure the stainless is inferior since they are already rusting. This is more or less a trial run to see how they fit and work. Can I cut the cast flange off of my manifolds to weld to the stainless? My other option is buy a flange from Australia at $118 shipped. It's mild steel.

Leave a comment:

-

Not too shabby bud, although looks a little cold. You can prolly run a little hotter and faster, especially on that 1/4" steel. See how high the weld has built up? Maybe try 5-10 more amps and moving at a faster travel speed. If they're still building up a lot you can turn the wire feed a little slower. Most importantly tho, KEEP WELDING! Don't just go out and do 10 mins of welding and call it a day, try to repeat your process of the better welds once you make them, it'll help you retain better habits/form

Leave a comment:

-

-

Been lurking on this thread for a while now thought I'd introduce myself in here since its where I'll be most lol.

Names Rudy and I dig fab work

Some of my work:

One-off bumpers, winch tub, roof rack, tire gate and ladder on this xterra

GTS/SP996 cages

International Scout bolt in cage

and some sick machine work i had done on my own project!

Last edited by gazolorean; 11-20-2015, 12:54 AM.

Last edited by gazolorean; 11-20-2015, 12:54 AM.

Leave a comment:

-

Question for the welders, I've got an old Hobart MIG and I'm trying to source a new gun for it. It's a Tweco gun but, it doesn't have a part number. Does anyone know what style this is? I know there's a Lincoln and miller style guns, but this is a bit different.

Leave a comment:

Leave a comment: