I'll be sure to post up what the final final design looks like. I'm the same in that I don't want to permanently modify the control arms, aside from the little bit of drilling and tapping I've done so far for height sensors.

Here's the design I've settled on, and I'll have pics of the actual welded-up versions as soon as I'm happy with them:

Here's the lower bag brackets, which will sit in the control arm pockets front and rear:

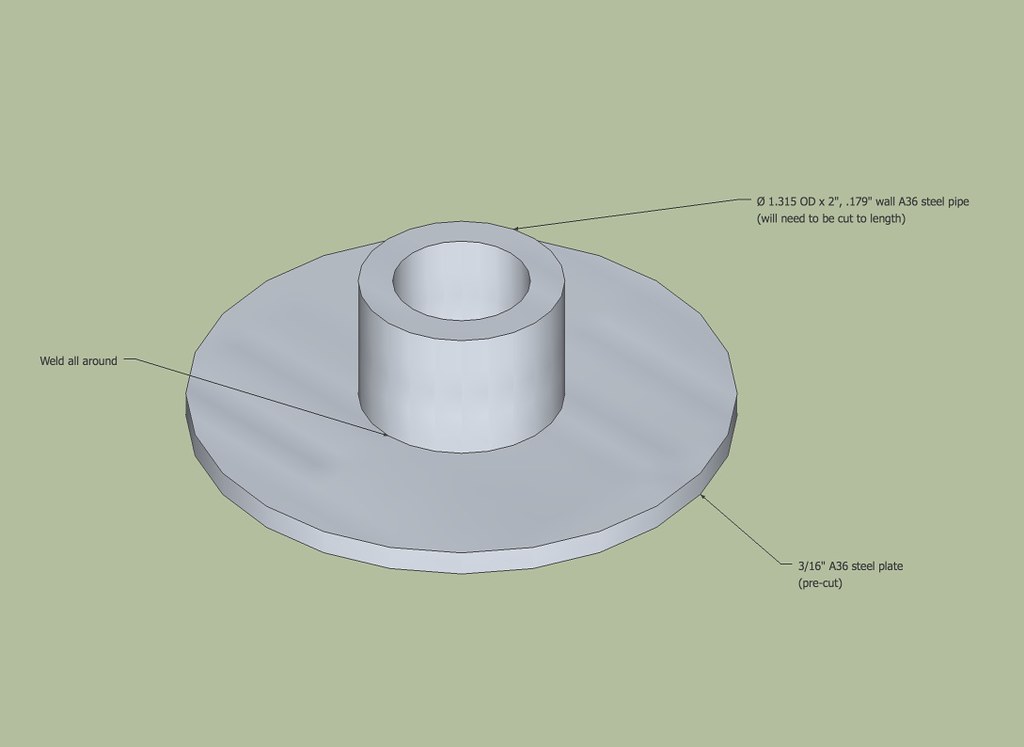

And the upper brackets:

This bracket will obviously sit in the upper spring cups. Once installed, I will drill a hole through the side to fit the air lines.

Finally, these are what I'm calling the "sandwich brackets:"

These will sit on the bottoms of the control arms, and attach via a long bolt to the nut inside the lower bag plates. The piece of structural pipe will loosely interface with the existing holes on the underside of the control arm, to help keep the bracket assembly located correctly.

If my maths are correct, and they rarely are, with the brackets the heights listed, I should be able to get good extension in either direction of the stock ride height, which is good, because the real point of putting this car on air is to get the damn thing up my insanely-steep driveway. Laying on its belly is merely a (major) bonus

. My plan is to install the brackets as designed, test the height at 90% extension on my driveway, and then trim the brackets down until the car only barely clears.

. My plan is to install the brackets as designed, test the height at 90% extension on my driveway, and then trim the brackets down until the car only barely clears.

), so I waited until today to finally test fit the MAEs. So, without further ado...

), so I waited until today to finally test fit the MAEs. So, without further ado...

Leave a comment: